When you place your order it will be assigned to a skilled craftsman who will build your knife from scratch. Each knife is given special attention giving you a product as close to custom as possible and ensuring you receive the finest cutting edge in the world. This process takes time and therefore we ask that you allow 3-4 weeks for your order to be completed and shipped. If you are requesting expedited shipment, please note that your order will ship with the requested method as soon as the product is available.

ABOUT THE TECHNOLOGY

DIAMONDBLADE, LLC, knife manufacturing company has focused on combining American craftsmanship with state of the art engineering and research to build technologically advanced knives. The United States Patent and Trademark Office has issued US Patent 8,186,561 covering Friction Forging® (solid state processing) of hand-held knives to Founder / Managing Partner, Charles Allen. DIAMONDBLADE, LLC. has exclusive rights to the patented technology resulting in unsurpassed knife performance. “Friction” Forging® is a localized forging process achieving high, transformation temperatures and high loads against a blade and then employing specialized techniques to achieve a rapid quench. Friction Forging® is performed on the blade in the area that becomes the edge. Friction Forging® uses a specially designed tool made from Polycrystalline Cubic Boron Nitride (PCBN), a material second only to diamond in hardness. During forging, the PCBN tool penetrates the blade while rotating, which creates frictional heating. When the tool is fully engaged, it moves along the eventual blade edge under high forging pressures, creating dynamic microstructure shearing that produce nanosize blade microstructures.

DiamondBlade knives have been awarded “1st Place” for three years in Field & Streams “Best of the Best” knife competition category.

"DiamondBlade knives will take and keep an edge like nothing else on the market."

– Field & Stream Magazine Awards Selection Committee Comments

SPECIFICATIONS

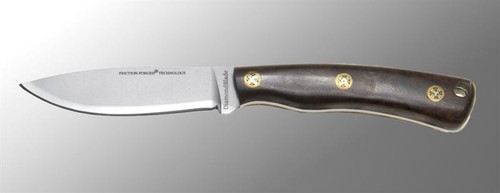

| Category | Summit | Item Number | 00102FG |

| Handle Details | Hand made, hand inleted set of 3 Mosaic Pins for a custom handle. | Steel | Friction Forged® D2 High Carbon Tool Steel |

| Blade Bevel | 4.5° wedge grind with a 16-18° sharpened bevel | Blade Depth | 1" |

| Blade Thickness | 0.118" - 0.120" @ spine | Blade Style | Drop Point |

| Blade Length | 3.750" | Knife Length | 8.750" |

| Knife Weight | 4.0 oz. | Spine Rc Hardness | 42-45 |

| Blade Rc Hardness | 65-68 | Sheath | Vegetable tanned, kydex lined, oiled split grained cowhide |

| Designer | Charles Allen | | |

Friction Forgi...

Friction Forgi... CATRA Machine ...

CATRA Machine ... ERT Machine

ERT Machine Rockwell "C" T...

Rockwell "C" T... Edge Strength ...

Edge Strength ... DB Testimonials

DB Testimonials Loading... Please wait...

Loading... Please wait...